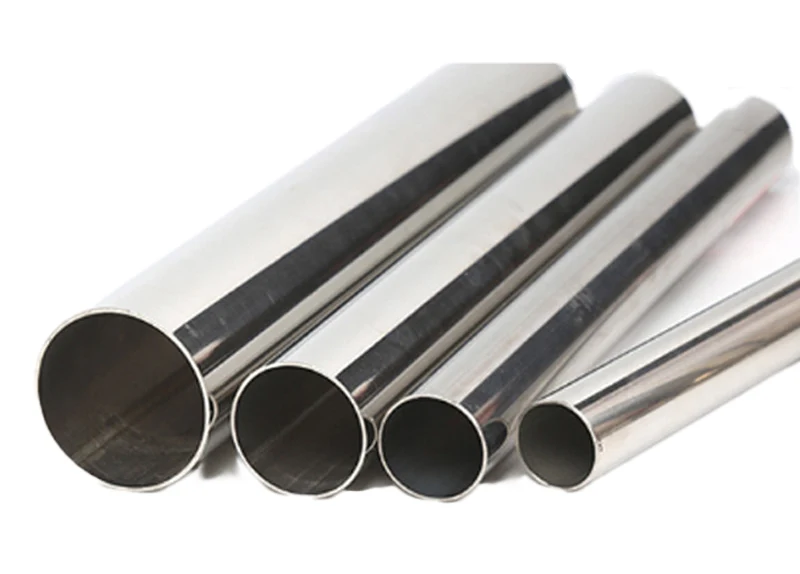

Stainless Steel Welded Pipe

Stainless steel welded pipe is made of stainless steel strip or plate, through the molding, welding and post-processing technology made of high-performance tubes, at the same time, corrosion resistance, high strength and economy, widely used in industry, construction, food and medical, environmental protection and other fields. The product adopts advanced welding technology such as TIG welding and high frequency welding, combined with strict quality testing standards (such as GB/T, ASME, DIN EN), and provides a wide range of materials such as 304, 316L, 2205, etc., and supports the spot supply and non-standard customization, to meet the needs of large-diameter, thick-walled, sanitary and other demanding scenarios!

Send Inquiry

Our stainless steel welded pipe adopts advanced welding technology, TIG welding base + MAG welding filler: to ensure that the weld seam is dense and free of porosity, with tensile strength of more than 520MPa, suitable for high-pressure fluid transportation. High-frequency resistance welding (ERW): high production efficiency, suitable for mass production, weld seam flat without oxidation. The post-treatment process adopts pickling passivation and polishing. The whole process of quality control, the use of ultrasonic testing (UT) and X-ray flaw detection (RT) to ensure that the weld is free of cracks, slag. Flare test, flattening test to verify the ductility, water pressure test to ensure the pressure-bearing capacity.

Specification parameters:

Material: 304, 316L, 2205, 310S and other raw materials are used according to the needs of different scenes.

Outside range: 12mm~2540mm

Wall thickness range: 0.5mm~90mm

Length customization: 1m~12m (standard) / can be cut in sections as required